Für Imker, die die Wachsausbeute maximieren und gleichzeitig die Reinheit erhalten möchten, bietet die Heißwasserextraktion eine zuverlässige, chemikalienfreie Lösung. Diese Anleitung beschreibt, warum diese Methode Alternativen übertrifft, bietet Schritt-für-Schritt-Optimierungstechniken und teilt reale Anwendungen für gefiltertes Bienenwachs.

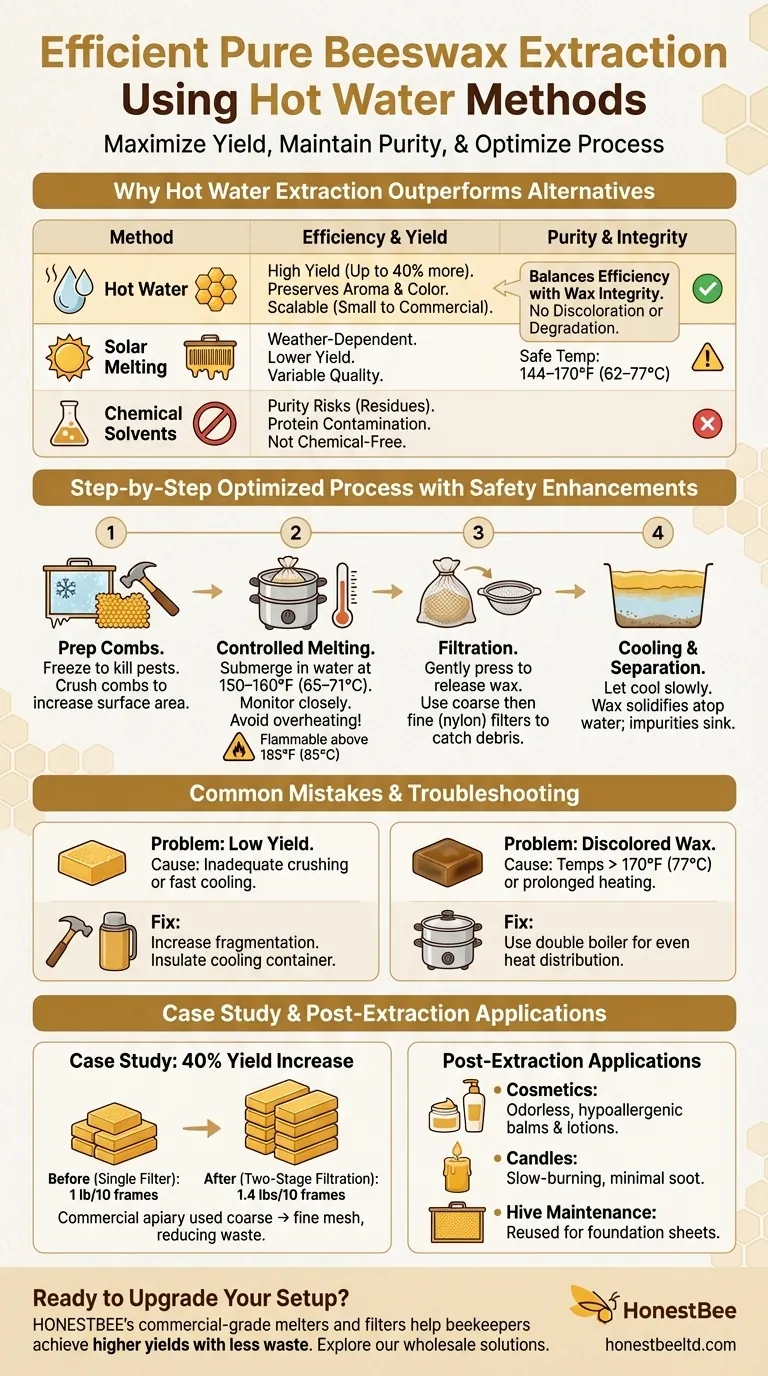

Warum die Heißwasserextraktion Solar- und chemische Methoden übertrifft

Die Heißwasserextraktion bietet ein Gleichgewicht zwischen Effizienz und Wachsintegrität – im Gegensatz zum Schmelzen durch Sonnenlicht (wetterabhängig) oder chemischen Lösungsmitteln (Reinheitsrisiken). Forschungen zeigen, dass sie das natürliche Aroma und die Farbe des Wachses durch den Betrieb innerhalb sicherer Temperaturschwellen (144–170 °F/62–77 °C) bewahrt und den Abbau vermeidet, der bei höheren Temperaturen auftritt.

Hauptvorteile:

- Höhere Ausbeute: Bis zu 40 % mehr rückgewinnbares Wachs im Vergleich zu Solarmethoden (siehe Fallstudie unten)

- Reinheitskontrolle: Keine Lösungsmittelrückstände; minimale Proteinkontamination

- Skalierbarkeit: Funktioniert für kleine Chargen oder kommerzielle Betriebe

Schritt-für-Schritt-Heißwasserextraktion mit Sicherheitsverbesserungen

Benötigte Materialien

- Doppelkessel aus Edelstahl oder spezieller Wachsschmelzer

- Käsetuch oder Polypropylen-Netzbeutel (200+ Mikron)

- Lebensmittelthermometer

Optimierter Prozess

- Waben vorbereiten: Rahmen einfrieren, um Schädlinge abzutöten, dann Waben zerdrücken, um die Oberfläche zu vergrößern.

- Kontrolliertes Schmelzen: Zerdrückte Waben in einem Netzbeutel eintauchen und das Wasser auf 150–160 °F (65–71 °C) erhitzen – heiß genug, um das Wachs zu schmelzen, aber unterhalb der Verfärbungsschwellen.

- Filtration: Den Beutel vorsichtig auspressen, um das Wachs freizusetzen. Verwenden Sie einen Sekundärfilter (Nylonstrumpf), um Ablagerungen aufzufangen.

- Abkühlen: Das Wachs auf dem Wasser erstarren lassen; Verunreinigungen sinken ab oder haften an den Behälterwänden.

Sicherheitstipp: Überhitzung vermeiden – Temperaturen genau überwachen. Bienenwachs ist über 185 °F (85 °C) entflammbar.

Häufige Fehler und Fehlerbehebung

Problem: Geringe Ausbeute

- Ursache: Unzureichendes Zerdrücken der Waben oder schnelles Abkühlen.

- Behebung: Zerkleinerung erhöhen; den Kühlbehälter isolieren.

Problem: Verfärbtes Wachs

- Ursache: Temperaturen über 170 °F (77 °C) oder längeres Erhitzen.

- Behebung: Einen Doppelkochtopf für gleichmäßige Wärmeverteilung verwenden.

Fallstudie: 40 % Ausbeutesteigerung

Eine kommerzielle Imkerei rüstete auf ein zweistufiges Filtrationssystem (Grobmaschen → feines Nylon) um und reduzierte so den Abfall. Nach der Extraktion erzielten sie 1,4 Pfund Wachs pro 10 Waben im Vergleich zu zuvor 1 Pfund.

Anwendungen von gefiltertem Bienenwachs nach der Extraktion

Reines Bienenwachs aus dieser Methode ist ideal für:

- Kosmetik: Balsame und Lotionen profitieren von geruchlosem, hypoallergenem Wachs.

- Kerzen: Langsam brennend mit minimaler Rußbildung.

- Bienenstockpflege: Wiederverwendung für Mittelwände.

Bereit, Ihre Extraktionsausrüstung aufzurüsten? Die gewerblichen Schmelzer und Filter von HONESTBEE helfen Imkern wie Ihnen, höhere Ausbeuten bei weniger Abfall zu erzielen. Entdecken Sie noch heute unsere Großhandelslösungen.

Visuelle Anleitung

Ähnliche Produkte

- Elektrische 8-Rahmen-Honigschleuder mit Selbstumlauf für kommerzielle Honigschleuderanlagen

- Professioneller thermostatischer konischer Honigschmelzer

- HONESTBEE 72 Rahmen Industrielle elektrische Honigschleuder für Imkerei

- Honig Konzentrieren Vakuum Heizung Verdickung Maschine Entfeuchter für Honig

- Hochwertige Honig-Luftentfeuchter-Trockner-Eindickungsmaschine für die Bienenzucht

Ähnliche Artikel

- Der Vorteil des Extraktors: Warum die Erhaltung der Wabe der Schlüssel zur Rentabilität von Bienenstöcken ist

- Die richtige Größe Ihres Honigschleuder-Extraktors wählen: Kapazität, Kosten und Effizienz ausbalancieren

- Optimierung der Zentrifugal-Honigschleuderung für verschiedene Bienenstocktypen

- Leitfaden für die Auswahl der besten Honigschleuder für die Imkerei

- Wie Sie die richtige Methode zur Honiggewinnung für Ihre Imkereibedürfnisse wählen